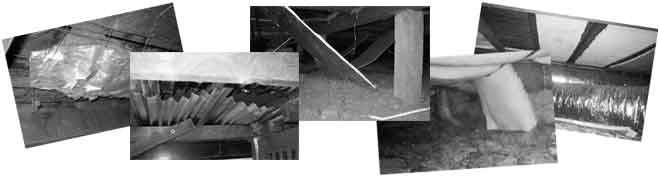

When we’re asked about all of the different types of underfloor insulation available, people are always shocked to see our scrapbook of underfloor horror stories.

If you’re researching all of the different types of underfloor insulation, this article is likely to confirm all of your worst fears. But don’t worry, we’ll also show you what to look for too so that you can bet on a winner and get the best possible result.

For over 20+ years, we’ve been inspecting the underfloor areas of homes and we’ve seen all of the types of underfloor insulation you can imagine. Materials like foam board, fibreglass batts, foil sheets and polystyrene held up with string, chicken wire, packing straps and nails!

So why do these solutions let us down?

Here’s some of the most common types of underfloor insulation disasters from our collection and why they should be avoided.

Insulation works by trapping air pockets in its fibres. This slows down air movement to keep your winter warmth in and the summer heat out. This means that the thicker and more secure the insulation the better! So you want to choose an insulation that stays thick and secure despite moisture, rodents and gravity.

You can choose the best insulation on the market, but if you don’t secure it well enough, you can never expect the best result. Here’s a few homes that learned the hard way …

1. Builder’s blanket held under the floor with wire.

Underfloor areas are exposed to the elements, particularly wind and water, and your insulation should be able to ‘weather the storm’, so to speak. As you can see, this insulation has not stayed in place long-term due to water damage and the wire has not held the material firmly against the floorboards.

As the material has become wet, the weight of the water has squashed the insulation, making the fibres permanently change shape. Parts of the materials have broken away, exposing the floorboards that are meant to be protected. This means that the insulation that remains is not nearly as effective as intended and the effort that it took to nail that wire under the floor was a waste of time and money. Water trapped in the insulation batts can also cause mould growth, and leak onto your plasterboard, causing staining and damage. If the insulation is installed behind metal cladding, water damage can cause rust and corrosion.

Read more about what happens if your fibreglass insulation gets wet here.

This video shows water being poured through polyester insulation. Its a great example of what you should be looking for when comparing different types of underfloor insulation and how they react to water.

2. Insulation batts tied up with packing strap, well, almost.

From a novice’s perspective, packing straps look like a quick and easy way to secure underfloor insulation batts. The idea is that the insulation batts are pressed between the joists and held up by their own friction (called “Fricton Fit” in the trade). The straps are then slung across the joists to support the insulation batts. The novice walks away feeling pleased at how quick and easy it was.

Unfortunately in a few short days the novice can probably expect something like this:

Gravity always wins. In less than a week, this particular home owner was devastated to discover the insulation sagging and hanging down everywhere! Even though he’d invested in premium polyester (which is proven to be the most robust and highest performing insulation there is), his securing method was a dismal failure.

3. Rigid polystyrene boards used to insulate under the floor

Polyestyrene boards are sometimes held up with small brackets or even just balanced on nails, which are pinned into the joists. While ideally we’d like to think floor joists are evenly spaced and that neat strips of polystyrene will fit perfectly in between, this is rarely the case. As you can see below, the wobbly edge doesn’t come close to covering between the joists and the nails have not been enough to hold the sheets up.

Using a rigid material to insulate under your floor is likely to be a case of ‘square-peg-round-hole’, or, more specifically ‘large-boards-tiny-access-door’. And, even if you can comfortably get the board under the house, it can be very clumsy to manoeuvre around, making it even harder to avoid gaps.

It’s such a shame because you can see how much effort would have gone in to installing these polystyrene boards, especially with all of that aluminium duct getting in the way!

Here’s an example of rigid reflective polystyrene insulation boards falling down over time, leaving the home unprotected:

Rigid foam boards balanced on nails becoming dislodged over time

4. Fibreglass bulk insulation held up with chicken wire

It’s not uncommon for rats to live underneath our homes, doing what they can to build themselves a cosy nest to breed it. Fibreglass bulk insulation contains loose fibres that can come apart over time, which makes it very appealing to rodents. As you can see below, this insulation has been torn apart and, even though the wire has stayed in place, the insulation has sagged and been pulled down by rats.

There are two things to look out for when it comes to rats and how they behave around different types of underfloor insulation.

1. If rats can get into the pocket between your floorboards and the insulation batt, they’ll nest there, so make sure you secure your insulation tight to stop any access. And remember, what’s secure today will need to still be secure in ten years’ time.

2. If rats can break the fibres apart with their claws, they’ll carry it away to use for bedding.

Looking for an insulation that is heat-bonded is the best way to avoid this. This means that there are no glues that can fail over time and the heat-bonded fibres are too strong for rats to disturb (in fact, they avoid it to save themselves from getting their claws caught!).

5. Reflective Zig-Zag Foil Sheets

Insulation is all about still air space. The better you can trap air and stop it from moving around, the better thermal protection you’ll get. No matter how good your fine motor skills are, preventing gaps is virtually impossible when you’re trying to match a zig-zag sheet like this end-to-end.

Rigid foam boards balanced on nails becoming dislodged over time

Remember, having enough space to trap the insulating still air layer is essential to thermal performance. The foil sheet pictured above is fitted up close to the floorboards, making a very slim space between the material and the underside of the floor. This makes the material very ineffective and the household living up above won’t be feeling much benefit at all.

So, where does that leave us?

Well, having compared all of the different types of underfloor insulation on the market, there’s only one that meets our strict criteria – given all of these insulation disasters we’ve seen over the years.

Polyester underfloor insulation is thick, strong and the only bulk insulation with fibres strong enough to secure with staples. It makes a huge improvement to your comfort and lasts the lifetime of your home. It’s safe to handle without gloves and won’t make you itch. In fact, it is so safe that a lot of the soft furnishings in our homes and bedding (pillows and doonas) are actually made out of the same material.

You can learn more about why we only recommend polyester underfloor insulation and watch a demo of how we install it in the video on this page.

But before you go … Got an underfloor insulation horror story to add to our collection? Let us know!

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]